IoT-Basics Was ist Predictive maintenance? Definition, Anwendung und Beispiele

Autor / Redakteur: Jakob Schreiner /Elisa MundtPredictive maintenance is one of the most tangible applications in Industry 4.0.In this way, condition data can be obtained from machines and systems can be waited proactively.Using a definition and examples from practice, this article explains what Predictive maintenance means and how it works.

Companies on the subject

NovaStor GmbHTrebing & Himstedt Prozeßautomation GmbH & Co. KGdoubleSlash Net-Business GmbHDefinition - Was ist Predictive maintenance?

Predictive maintenance (zu Deutsch: vorausschauende Instandhaltung) bezeichnet per Definition einen Wartungsvorgang, der auf der Auswertung von Prozess- und Maschinendaten basiert und findet sich vor allem im sprachlichen Kontext der Industrie 4.0.This real-time processing of the underlying data enables forecasts that form the basis for a need-based maintenance and consequently the reduction of downtimes.In addition to the interpretation of sensor data in a combination of real-time analysis technology and in-memory database, this requires a higher access speed compared to hard disk drives in comparison with hard disk drives.If everything succeeds, it is possible to commission a technician to fix a problem before it arises.Because: only if systems, machines and processes work perfectly can economic goals be achieved.

With the help of Predictive maintenance techniques, the condition of devices in operation is determined to predict when maintenance should be carried out.As a result, cost savings against routine or time -dependent preventive maintenance can be achieved, since tasks are only carried out if they are actually necessary.

The main goal of Predictive maintenance is to create the most precise planning of maintenance as possible and to avoid unexpected failures of systems.With the knowledge of when which devices have to be serviced, resources for maintenance work such as spare parts or people can be planned better.In addition, the system availability can be increased by converting "unplanned stops" into ever shorter and more frequent "planned stops".Further advantages should be a potentially longer lifespan of the systems, increased system security, fewer accidents with negative effects on the environment and an optimized spare parts handling.

Wie funktioniert Predictive maintenance?

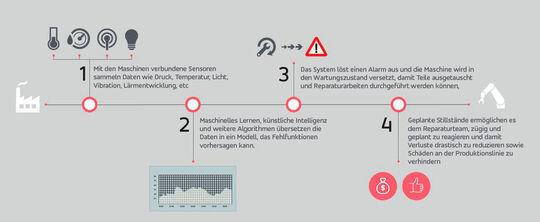

The predictive maintenance categorizes the constitution of systems, for which it is checked either periodically (offline) or continuously (online).Ideally, it becomes possible to design an upcoming maintenance not only for a maximum of cost, but also performance-efficient, i.e. before the machine threatens a loss of performance.In order to limit interruptions of the regular system operation to a minimum, a large part of the predictive inspections can be completed in parallel to the operation of the system.

To assess the current state of a device, a review using infrared, acoustics (partial discharge and ultrasound), corona detection, vibration analysis, sound level measurements can be used.Of course, the device must not be impaired or even damaged by such test methods.A recent approach is to link the knowledge gained from this with process performance data, which are particularly available in collaborative process automation systems (CPAS).

If you want to establish predictive maintenance effectively and in the long term in your company, you should follow the following three work steps:

Predictive analytics and big data

A great difficulty in dealing with predictive maintenance is the processing of the huge amounts of data.Because in order to make reliable statements about the state of machines and systems and thus to be able to capture expected disorders as quickly as possible, it is necessary to collect large amounts of data.These must be saved, processed and used with intelligent algorithms.

Due to the huge amount of data, techniques and databases from the big data environment, such as EDGE computing, are particularly suitable for predictive maintenance.

The data not only include the condition of the machines and systems themselves, but also their environment: For example, parameters such as temperature or humidity are also recorded and evaluated.Overall, the data can be very different and are available in different formats.Due to these many different data and formats as well as the large amounts of data, databases must provide huge capacity.It is important to know that the size of the database and the intelligence and performance of the analysis algorithm are essential for the quality and reliability of the knowledge obtained: The greater the database and the more intelligent and sophisticated the algorithm, the more reliable the findings are.After recording, the measured values and diagnostic data are transmitted via networks to service centers or to the manufacturer.The Internet of Things (IoT) serves as the basis here.

Nevertheless, it is essential to update and process the large amounts of data that are collected during the foresight maintenance in order to be able to read trends and developments from possible changes.

Data science

IoT-Basics: Big Data Technology Base

Vorteile von Predictive maintenance

If predictive maintenance is used correctly and efficiently, it can provide a variety of advantages - both for the manufacturer and the user.Here are the most important advantages at a glance:

IoT-Basics

What is big data?Definition, meaning and architecture

Beispiele für Predictive maintenance

Predictive maintenance is already being used in many areas today.The predictive maintenance is not only interesting for the manufacturing trade, but also for any mobility services - be it in aviation, in vehicles or trains - or wind power plants.With the help of the predictive maintenance, the downtime of wind turbines can be almost completely avoided.

Predictive maintenance in motor vehicles

Predictive maintenance is also becoming increasingly important in the area of mobility - including the maintenance of motor vehicles.With the help of extensive data surveys by sensors in the engine or chassis of vehicles, expensive repairs or failures can be avoided at an early stage and preventive activities can be initiated.This includes, for example, the replacement of a damaged vehicle part during the next workshop visit before the part fails at some point.The foresighting maintenance goes one step further when vehicles are networked: You can transmit data online and automatically to service workshops or the manufacturer.

Predictive maintenance in aviation

Airplanes only earn money when they are in the air.If an aircraft fails due to mechanical damage, this irrevocably leads to high costs for the airline.So it is very much because of being able to identify possible damage in advance and thus be able to avoid a failure or even accident. Einsatzfelder für Predictive maintenance in aviation sind beispielsweise Turbinen oder hydraulische Pumpen.With its "SkyWise" data platform, Airbus has already launched a corresponding project in 2017 that enables aircraft engineers to intervene early in the event of error detection and let the component replace before failure.

Predictive maintenance in rail transport

The use is similar in rail traffic.Here, too, repairs should be better planned with Predictive maintenance and knowledge about the life cycle of certain components should be gained.Predictive maintenance can help in rail traffic that a surprising failure of a train can be avoided.The reason for this is that it can be planned in advance when the damaged train section will be repaired in order to prevent disorders for the course of the company.By analyzing and using the data recorded, correct repair instructions can be selected, suitable spare parts can be provided and the failure is kept as short as possible.

Predictive maintenance

Von Reaktiv zu Proaktiv: In 6 Schritten zu Predictive maintenance

Voraussetzungen für erfolgreiche Predictive maintenance

Grundsätzlich ist Predictive maintenance sinnvoll, aber es müssen gewisse Rahmenbedingungen erfüllt sein.However, these are not fulfilled by every company.

Let us take a company, for example, which has 100 different machines in production.Despite the appropriate maintenance according to the manufacturer's recommendation, 10 machines per year fail.That would mean that ten years of history would be necessary in order to observe at least one damage for each machine from which the algorithm could learn.This period is unrealistic and would still not generate a lot of information. Für dieses Unternehmen lohnt sich der Einsatz von Predictive maintenance also nicht.

Lohnen kann er sich hingegen für Unternehmen, die häufiger denselben Maschinentyp im Einsatz haben, bei denen Maschinen häufiger ausfallen oder für solche Unternehmen, die Maschinen selbst herstellen und Predictive maintenance nicht (nur) für ihre eigene Produktion nutzen wollen, sondern für die Maschinen, die sie selbst verkaufen.

Ob der Einsatz von Predictive maintenance im Unternehmen sinnvoll ist, hängt von verschiedenen Faktoren ab und muss individuell geprüft werden. Ob der Mehrwert eines Predictive maintenance-Projekts die Komplexität rechtfertigt, hängt also von vielen Faktoren ab und muss dementsprechend im Einzelfall geprüft werden.

Market insight

21 Predictive maintenance Start-ups und Spezialisten

Preventive VS. Predictive maintenance

The predictive maintenance ("predictive") differs from the preventive maintenance ("preventive") in the fact that it is based on the actual condition of the systems and not on the average or expected lifespan to predict when maintenance is required.

Even with preventive maintenance, the goal is to avoid downtimes. Der Unterschied zur Predictive maintenance liegt jedoch darin, dass keine live von der Maschine erhobenen Daten zur Wartung genutzt werden, sondern Wartungsmaßnahmen und die Überwachung anhand bereits im Vorfeld festgelegter (regelmäßiger) Intervalle durchgeführt werden.Preventive maintenance is based on the theoretical failure rate and therefore ignores the actual system performance.Dials are planned on the basis of calendar data or use.It should be ensured that the maintenance time is neither too early nor too late.For example, most of the forklift manufacturers recommend carrying out preventive maintenance every 150 to 200 operating hours.

Since companies, their facilities and their daily operation can differ greatly, unnecessary maintenance can occur when using preventive maintenance.In addition, when using the preventive maintenance, a company runs the risk of exchanging parts that still work perfectly and would still have done it.

Mehr zum Thema Predictive maintenance:

Web-Konferenz

Predictive maintenance

(ID: 45100878)

Tips to do your electrical installa...

Companies in the Pinneberg district...

Maintal is becoming a smart city th...

New subway workshop and wash bay in...