DLR at a glance

The German Aerospace Center (DLR) is the research center of the Federal Republic of Germany for aerospace.

A contribution from DLRmagazine 169

The railway is one of the most important inventions of industrialization. It transported people and goods over long distances at speeds that were unimaginable at the time. The world of locomotives, wagons and rails has long been associated with a lot of high-tech. Now the railways are facing a new challenge: entering the world of digitization and automation. The DLR transport research experts are certain: things are happening on the rails – and quite a lot, as this insight shows.

Automation, new communication technologies and standards, and the use of machine learning and artificial intelligence have the potential to make rail transport much more attractive and competitive. They enable significantly higher capacities on the tracks and more efficiency overall. At the same time, they promise less energy consumption and more safety, punctuality and comfort. There is a great need for forward-looking technologies and innovative solutions for tomorrow's railways: "State-of-the-art and climate-friendly rail transport plays a central role in the traffic turnaround," Prof. Dr.-Ing. Karsten Lemmer for sure. He is a member of the DLR Executive Board and responsible for innovation, transfer and scientific infrastructure. “Passenger and freight traffic will continue to increase globally, while at the same time there is a growing need for mobility that is as climate-neutral as possible. In this situation, more intensive use of rail transport can be an important part of the solution.”

Automated railway operations and the human factor

Automated and connected driving is a megatrend and innovation driver in road traffic. In rail transport, driverless subways and metros are already on the road in many European cities. Automated freight trains transport iron ore in the Australian outback to the loading ports on the coast. In some areas, rail is one of the pioneers in automation. However, this development cannot be easily transferred to the entire rail network. Because high-speed trains use the same route network over large parts as the much slower passenger and freight trains, which makes the starting point for automated and networked rail operations considerably more complicated. In addition to technology, people will continue to play an important role.

“With increasing automation, the role of humans changes – instead of being active on site themselves, they fix errors or monitor, check and take care of maintenance. It is important to recognize and understand whether the automation is faulty, is acting unexpectedly and why," explains Dr. Jan Grippenkoven. He works at the DLR Institute for Transport System Technology, where the interaction between humans and automation in the railway sector is examined. Among other things, the scientists are investigating the psychological challenges associated with this in studies using special simulators. An example is the RailSET test laboratory (Railway Simulation and Environment for Train drivers and operators). It realistically depicts the workplace and the tasks of train drivers - as a virtual track including signals and level crossings. In addition to information and assistance systems, different degrees of automation can also be simulated. “Even with a low degree of automation, monotony and fatigue quickly occur. You lose your focus on the situation and your ability to intervene quickly is limited. The probability of errors increases,” explains Grippenkoven. Train drivers and dispatchers must not be completely decoupled from the processes and must know the importance of their task. Because they are responsible for hundreds of passengers and tons of cargo.

Key technologies for automated rail: train-to-train communication and train localization

A train usually consists of several cars. If these have their own drive, they are called railcars. The individual parts of the train are still connected today with mechanical couplings. These transmit tensile and compressive forces when accelerating or braking. There are a variety of different mechanical clutches around the world, some are semi-automatic, others fully automatic. In freight transport, the individual wagons are often attached and detached by hand, which is very complex and time-consuming. That is why efforts are currently being made across Europe to convert to "digital automatic couplings" (DAC). This automatically connects freight wagons and their power, data and compressed air lines.

The researchers at DLR are thinking a little further into the future and are relying on new communication technologies and standards such as 5G mobile communications and innovative localization methods. With the “dynamic wing” concept, the individual parts of the train follow each other closely spaced. They are no longer connected mechanically, only digitally. The virtual clutch based on data takes the place of the real clutch made of metal. In this way, wagons and trains can independently connect to form longer units during the journey and separate again if necessary. In order for this to work reliably, the distance between the units must be continuously calculated and corrected if necessary - of course everything is also digital and automated. “Dynamic wings can make rail operations much more flexible and efficient. Shorter distances between the trains or train parts also enable higher transport capacities," says Holger Dittus from the Vehicle Energy Concepts department at the DLR Institute for Vehicle Concepts. “In high-speed traffic, intermediate stops can only be served by a single part of the train without the main train having to stop. In this way, the maximum speed of the existing routes can also be better utilized.”

The most important technological requirement and at the same time the greatest challenge with dynamic wings and virtual domes is the safe and fast communication between the trains or train parts and their exact localization. For both, it is important to find solutions that are independent of the rail infrastructure and work at high speeds. They must also be redundant to ensure reliable operation even if one system fails. Global satellite navigation systems as well as radar and lidar sensors use radio waves or laser beams to measure position, distance and speed. In addition, the DLR Institute for Communications and Navigation is investigating and testing the use of magnetic field signatures. A lot of metal is used in the rail infrastructure (tracks, lines, bridges, cables, reinforced concrete walls). This influences the magnetic field and also interferes with a magnetic compass, for example. The disruptions vary from place to place. “This is exactly what we use to get information about position, track and speed. This method also works very well in tunnels,” adds Dr. Andreas Lehner from the DLR Institute for Communications and Navigation.

For example, mobile radio technology can be used for communication between the trains or train components. A high level of reliability, security and short latency times are also important. This is the physically caused delay in the transmission of data. With the latest 5G standard, the latency is up to less than a millisecond. In this context, DLR has developed, among other things, a new type of module that transmits radio waves in the millimeter range - a frequency range that is to be used more in mobile communications in the future with 5G and 6G. Initial investigations have shown that stable and secure communication can be established up to a distance of around 130 meters.

Intelligent freight wagons and intermodal cargo terminal

“Block trains” currently dominate freight transport. They transport a large, uniform amount of cargo, such as cars or containers. The so-called single wagon transport, in which a freight train consists of wagons with freight from different customers, is associated with complex processes and rigid operational procedures. 30 to 40 percent of the costs are incurred just for assembling and separating the train. Numerous manual coupling processes lead to long downtimes of the wagons. This is why the average speed in Germany for single wagon traffic is only 18 kilometers per hour. Rail is therefore not very attractive, especially for the growth sectors of courier, express and parcel services, groceries and general cargo. To change that, a team from several DLR institutes is working on a forward-looking concept for rail freight transport as part of the major Next Generation Train (NGT) project. It includes a railcar train, the NGT Cargo, and a new type of freight station, the Next Generation Station (NGS) Logistics Terminal.

The aim of NGT Cargo is to reduce transport times, be more flexible and punctual, and reduce costs. The researchers want to achieve this by making the train concept modular wherever possible and providing each individual car with its own uninterruptible power supply. "This is the basis for any form of automation and is essential for reliable data communication and the digitization of many vehicle functions," explains David Krüger from the DLR Institute of Vehicle Concepts.

The automated NGT cargo trains are assembled from individual cars and powerful power cars and automatically coupled as required. The train combination stays together for as long as it makes logistical sense, after which the individual cars separate again. “Each individual intelligent freight car knows its destination station and, if necessary, receives updates from the traffic control center. It has its own drive, based on electric motors, and a battery that stores the energy recovered during braking. As a result, the individual wagons can shunt independently, and there is no need for shunting personnel, shunting locomotives or overhead lines,” says DLR scientist Krüger, describing the concept. In addition, the individual wagons can independently drive the last few kilometers to the respective customer. They are equipped with the appropriate sensors for this purpose. For example, they can be localized at any time and customers can receive precise information on the current status and expected arrival time of their freight.

The NGS Logistics Terminal is the right station for this train service. It forms the interface between NGT Cargo and local freight traffic. These intermodal freight yards connect rail with road or air space at logistically favorable hubs. Autonomously driving trucks or cargo bikes or drones for particularly urgent goods then bridge the "last mile" to the destination. The main components of the Logistics Terminal are racks positioned along the train wagons. Here the goods are pre-sorted and temporarily stored directly on the track. The pre-sorting, but also the loading and unloading works automatically via stacker cranes, elevators and moving floors.

Predictive Maintenance

The rail network in Germany is around 38,000 kilometers long. In addition to the tracks themselves, signal boxes, switches and overhead lines also have to be checked and maintained regularly. This is done with measuring vehicles and inspections with appropriate measuring devices. Such complex and labour-intensive procedures are necessary to locate damage, replace components as a precautionary measure and determine the condition of the rail infrastructure. “Machine learning and artificial intelligence enable a whole new dimension, namely predictive maintenance. This means that we also receive a forecast of how the material or components will develop under the given conditions. In this way, you can prevent the risk of possible damage, avoid system failures and carry out maintenance work in a much more targeted manner," says Dr. Jörn Groos from the DLR Institute for Transport System Technology the possible future scenario.

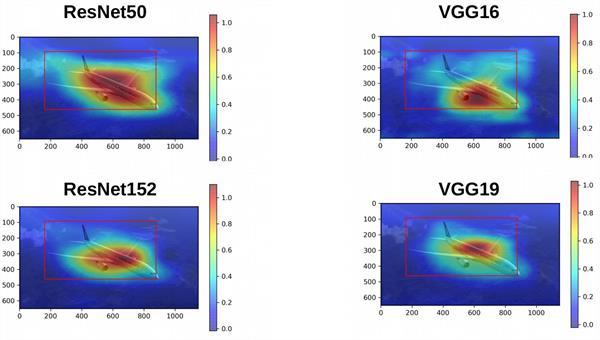

In order for artificial intelligence to be able to do this, it must first be fed with a great deal of information and repeatedly trained using examples. Data from sensors and cameras that ride on the trains play an important role in this. With their help, a very precise digital image of the infrastructure can be created. Historical data series and the knowledge and experience of experts are also incorporated into the algorithms and models. The DLR scientists are working on systematically collecting information and implementing it scientifically in such a way that artificial intelligence can work with it.

In the area of port railways, DLR has put this technology into practice. Port railways ensure the transport of goods within sea and inland ports. They must be fully operational at all times in order to reliably process time-critical logistics orders. Together with the rail technology company Vossloh Rail Services, the software developer IS Predict and the Braunschweig port operating company, DLR has developed what is known as embedded condition monitoring and tested it in shunting operations. To do this, the project team equipped a shunting locomotive in the Braunschweig port with a multi-sensor system. It consisted of cameras, acceleration and yaw rate sensors, delivered high-resolution image data and continuously measured the vibrations. From this, the researchers obtained information about the condition of the track infrastructure and the position data. At the same time, this was the basis for developing a corresponding AI-based analysis method. The system managers were then able to view the results – i.e. an overview of the current condition of the rails and any damage – using an interactive map. “Even today, such systems can provide valuable information for the operations management of small industrial railways in order to carry out manual inspections in a more targeted and effective manner. The further development of the analysis methods will make it possible to continue to reduce the proportion of manual inspections that involve staying in the track area in the future," summarizes DLR researcher Groos.

A holistic perspective for the future

The world of rail ranges from futuristic high-speed trains to intercity, regional, local and freight transport and thus forms an exciting and at the same time challenging starting point for science. At the same time, it harbors enormous market potential for technologies and business models. “Rail transport research at DLR has comprehensive expertise in almost all technologies relevant to the railway sector and combines this with a holistic perspective that combines economic, ecological and social aspects. This lays the basis for a successful transfer to the market. Our researchers are internationally sought-after contacts when it comes to optimizing existing systems and designing completely new concepts - always in close cooperation with partners from industry," summarizes Karsten Lemmer.

Denise Nüssle is a press editor at DLR.

These DLR institutes and facilities conduct research in the field of rail transport |

| Institute for Aerodynamics and Flow Technology |

| Institute for building methods and structural technology |

| Institute for Data Science |

| Institute for Vehicle Concepts |

| Institute for fiber composite lightweight construction and adaptronics |

| Institute for Communications and Navigation |

| Institute of Aerospace Medicine |

| Institute for Material Physics in Space |

| Institute for Software Technology |

| Institute for System Dynamics and Automatic Control |

| Institute for Systems Engineering for Future Mobility |

| Institute for Transport Research |

| Institute for Traffic Systems Engineering |

| Institute for Materials Research |

DLR at a glance

The German Aerospace Center (DLR) is the research center of the Federal Republic of Germany for aerospace.

Tips to do your electrical installa...

Companies in the Pinneberg district...

Maintal is becoming a smart city th...

New subway workshop and wash bay in...