In addition, their lifespan fluctuates because they constantly unload themselves through the chemical process within the cells.A good alternative are series-ready sodium-ion batteries, so-called salt water storage.The article explains their strengths and weaknesses.

Salt water batteries are similar from the structure of a lead battery - but with one important difference: they only use non -toxic and environmentally friendly substances.

Structure and special properties

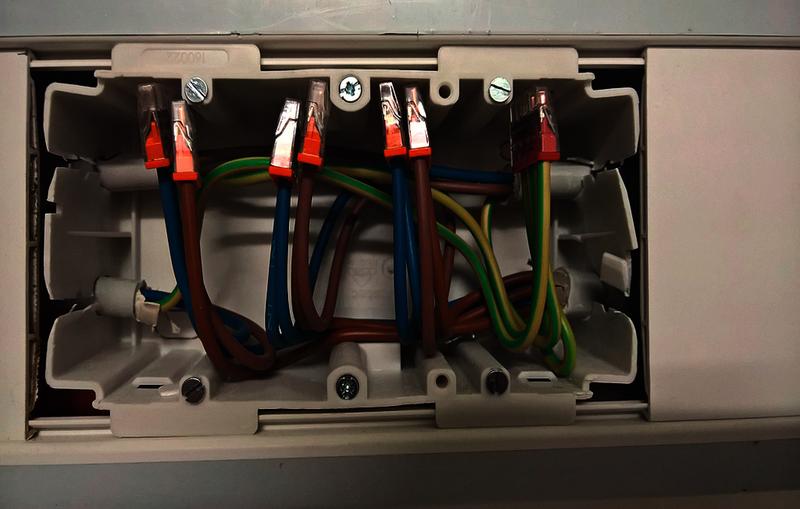

The aqueous sodium-ion battery cell is made up of a sodium-titan phosphate connection as an anode and an alkali-mangan oxide connection as a cathode.The thickness of the electrode layers is up to 3 mm.An aqueous solution made of sodium salts forms the electrolyte, while the separator consists of cellulose fibers.Power collector and battery housing are made of sustainable materials such as stainless steel, carbon or titanium (picture).

With their structure and the salt water electrolyte, the wet cells of the batteries can neither catch nor explode.Therefore, the strict certification according to IEC 62619: 2017 or.DIN EN 62619 (VDE 0510-39) [1], according to which a cell has to prove in a so-called propagation test that it is secured against thermal through.

The average cell voltage of a salt water battery is about 1.6 V, the usable voltage range between 1.25 V and 1.8 V.The cell voltage of lithium-ion batteries is more than twice as high.

In contrast, salt water batteries can be unloaded up to a discharge tension of 0 V.In the deep -downloaded state, the salt water batteries can even be stored for a long time and are without problems with a new load with direct current without problems.

A family from the Belgian mena relied on this special feature in a new building inaugurated in 2019 and, in addition to a spectacular glass -integrated photovoltaic system.With a maximum power of 7.2 kW, the salt water battery supplies the family, especially at night with the self -produced solar power, without a deep discharge being problematic.

There are still weakness in energy density and weight

Salt water batteries are not suitable for every application.Compared to lithium-ion batteries, they are larger and heavier and have a lower energy density.They are therefore intended for stationary applications on a stable surface.The increased weight can lead to additional effort when installing on site, since transportation is only possible with sack carts or in the case of commercial storage using staners.

Due to their C-rate of 0.19, salt water batteries are not created to be loaded or unloaded within a very short time.With a capacity of 60 kWh, for example, you only perform 11.4 kW in a loading or unloading process.The need is useful to further increase the capacity of the memory in order to create a greater performance.

The capacity of salt water storage is designed for a lifespan of over 15 years.Average capacity degradation of a maximum of 2.5 % per year leads to an average capacity degradation of the electrodes and the evaporation of the electrolyte.The evaporation of the electrolyte uses at temperatures from 50 ° C and promotes gas development that harms the capacity of the memory sustainably and irreversibly.

So far hardly any guidelines or standards for salt water batteries

In sales, these disadvantages move into the background.Sales engineer Nico Knodel from the Austrian manufacturer Bluesky Energy is open with the weaknesses of the sodium-ion batteries in conversation with installers and end customers: "Most of the time I mention them first and openly tell the customer that he is for a big, heavy and sluggishInterested energy storage."

But he also knows how to present the advantages of technology.The building law regulations for salt water storage are far less strict than for lithium-ion batteries.While these are accommodated in separate fire protection rooms, a salt water memory can be set up in a utility room together with other devices such as dryers or washing machines.There you can do without a ventilation or air conditioning system as well as an acid cutting pan.Space -saving possibilities under stairs or garages kept in frost -free are particularly popular.

Since salt water storage is not corroded and are completely maintenance -free, unreserved access during operation is not absolutely necessary.Thus, the customer saves the construction or renovation costs, which is why salt water storage as well as the GreenRock model from Bluesky Energy is generally payable within ten years.

In addition, there are diverse funding programs for environmentally friendly salt water storage.The Flemish government supported the energetic renovation of a nursing home in the Belgian Halen, including the installation of a salt water battery, with a one -off special funding of around 52,000 euros.In some regions of Germany, too, salt water stores are better promoted than lithium batteries.For the Schönau electricity works, the funding is, for example, 25 % higher.

Installers benefit from sustainability requirements

Nico Knodel has now noticed a rethink with many end customers.Not only that you use solar systems and storage to rely on the highest possible self -consumption of your clean energy.You are now asking for sustainable systems as an alternative to lithium batteries.This makes salt water technology interesting for more and more installers.

“Some electrical installers already consider the fundamental change away from lithium-ion batteries to more sustainable technologies. Dabei spielt auch der Sicherheitsgedanke eine immer größere Rolle, da sie keine hochentzündlichen Speicher mehr verkaufen wollen", erklärt Knodel.Salt water stores, on the other hand, are already declared as harmless well during transport and thus save the installers a lot of effort in transportation.Lithium-ion batteries, for example, may according to the Ordinance UN 38.3 [2] can only be transported in the original packaging and specially secured.

Installation und Inbetriebnahme vor Ort können dank moderner Plug-&-Play-Systeme bereits in drei Stunden erledigt werden.The uncomplicated salt water batteries can also be put into operation by every master or journeyman who has completed a corresponding training.It is not necessary for the manufacturer to move up with a specialist in customers.“The two -stage sales are ideal for us as a manufacturer. In Schulungen lernen die Installateure neben den technischen Details auch viel über die optimale Auslegung der Salzwasserbatterien", erläutert Vertriebsingenieur Knodel.

Since the start of its certification program in March 2019, Bluesky Energy has trained more than 200 small and medium-sized electrical operations from the roof region.The electrical engineers learn how to clearly compare the end customer the cost advantages compared to other systems.

According to Knodel, the acquisition costs and the infrastructural additional costs are comparatively low in salt water batteries.

Author: h.Mayer

Literature:

[1] IEC 62619: 2017-02: Secondary Cells and Batteries Containing Alkaline or Other Non-Acid Electrolytes-Safety Requirements for Secondary Lithium Cells and Batteries, For Use in Industrial Applications.DIN EN 62619 (VDE 0510-39): 2017-11: Accumulators and batteries with alkaline or other non-acidic electrolytes-safety requirements for lithium batteries and batteries for use in industrial applications (IEC 62619: 2017).

[2] United Nations Recommendations on the Transport of Dangerous Goods.German: Federal Institute for Materials Research and Testing (BAM): Recommendations for the transportation of dangerous goods -manual on exams and criteria.Berlin, 6.Edition/1.Change 2019.

The full article can be read in our specialist archive.

Tips to do your electrical installa...

Companies in the Pinneberg district...

Maintal is becoming a smart city th...

New subway workshop and wash bay in...